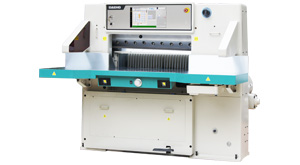

i Cutter, an intellectual paper cutter, has been domestic first equipped with CIP4 support function which is the information technical standard related to printing, so that most of operations can be done through the 15” LCD touch screen, and whoever to use PC can handle easily the cutter by application of innovative user interface. Also all programs required for control of machine can be upgraded easily and it is possible to link with other CIP4 compatible machine by automated scheduling function and network support.

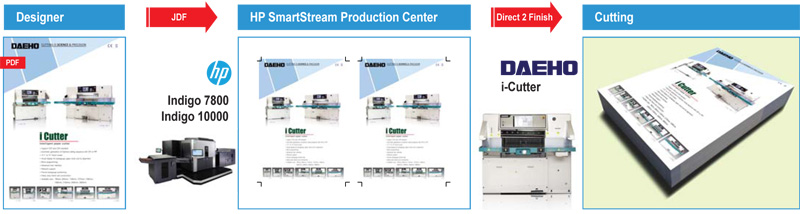

DAEHO i-Cutter series can be integrated to HP INDIGO workflow and support fully automated cutting jobs. HP Indigo now can make Job Ticket while printing process. This Job Ticket can is scanned from DAEHO i-Cutter (with CIP4 module and HP integration option) and DAEHO i-Cutter makes optimized cutting sequence automatically from Job Ticket. This function dramatically reduces READY TIME for cutting jobs. Also it supports faster and more convenient cutting jobs. In our experiments, it can increase cutting efficiecny 170% more.

Features

- Supports standard JDF format for CIP4 which is the information standard of printing industry

- Most of controlling can be done on the 18″ Wide TFT-LCD touch screen

- Displays visually backgauge position, paper alignment state and various information of machine

- Fast and convenient cutting is available by intelligent control program

- Block programming function

- Process move, copy and backup are available through external memory

- It is supported for user to control the timing that clamp comes up so that faster cutting is available

- Programs which are needed for machine control can be upgraded easily

- High speed cutting is available by optimizing cutting process

- Advanced User interface provides easy view and easy to use

- Important variables are protected by password. By storing factory settings separately so that system can be restored from error which is cause by misuse of user.

- Control program upgrade

- Paper sheets counter (option)

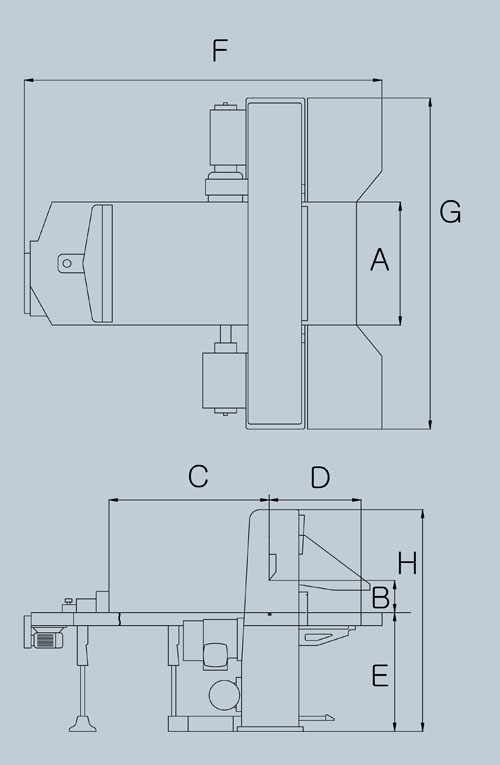

Specification

| Model | i-1580 | i-1370 | i-1160 | i-860 | i-780 | i-570 | |

| A Cutting width ㎜ | 1580 | 1370 | 1160 | 860 | 780 | 570 | |

| B Cutting opening ㎜ | 165 | 165 | 165 | 155 | 140 | 120 | |

| C Cutting depth ㎜ | Max. | 1580 | 1370 | 1160 | 860 | 780 | 570 |

| Min. | 38 | 30 | 30 | 30 | 25 | 15 | |

| D Front table length ㎜ | 720 | 720 | 720 | 635 | 650 | 450 | |

| E Table height ㎜ | 900 | 900 | 900 | 865 | 900 | 865 | |

| F Machine length ㎜ | 3210 | 2715 | 2655 | 2035 | 1920 | 1300 | |

| G Machine width ㎜ | 3140 | 2630 | 2420 | 1990 | 1640 | 1180 | |

| H Machine Height ㎜ | 1720 | 1660 | 1660 | 1535 | 1500 | 1390 | |

| Cutting Speed r.p.m | 48 | 48 | 48 | 45 | 45 | 38 | |

| Power ㎾ | Main motor | 5.5 | 4 | 4 | 4 | 2.2 | 1.5 |

| Backgauge | 1 | 0.5 | 0.5 | 0.5 | 0.5 | 0.2 | |

| Air table | 0.4 | 0.4 | 0.4 | 0.4 | 0.2 | 0.2 | |

| Backgauge speed m/min | Max. | 20 | 20 | 20 | 20 | 20 | 10 |

| Min. | 1 | 1 | 1 | 1 | 1 | 1 | |

| Driving System | Double Clank |

Double Clank |

Double Clank |

Single Clank |

Single Clank |

Single Clank |

|

| Clamp pressure ㎏ | Min. | 200 | 200 | 200 | 200 | 200 | 500 |

| Max. | 4500 | 4500 | 4500 | 4500 | 3000 | 1500 | |

| Machine weight ㎏ | 5800 | 5000 | 4150 | 2440 | 2030 | 1000 | |

⊕ Subject to change and improvement without notice.

For more information about i Cutter, please do not hesitate to contact us.

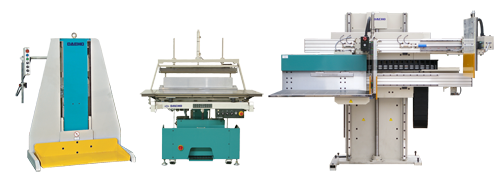

See another paper cutters